Using Biotech to make living, self-sustaining buildings is a new level of innovation which could revolutionize construction engineering. The ‘Materials For Life‘ Project in Wales (UK) is literally producing stones which self-repair and resist erosion!

The University of Cardiff (Wales) leads a team with the University of Bath (SW England) and the University of Cambridge in the first ever UK trial of a living, self-healing concrete prototype. Since it is estimated that around £40Bn (€56Bn) a year is spent on building repair and structural maintenance in the UK alone (and $2.2Tn in the US), this self-healing organic concrete could change the future of building materials.

The University of Cardiff (Wales) leads a team with the University of Bath (SW England) and the University of Cambridge in the first ever UK trial of a living, self-healing concrete prototype. Since it is estimated that around £40Bn (€56Bn) a year is spent on building repair and structural maintenance in the UK alone (and $2.2Tn in the US), this self-healing organic concrete could change the future of building materials.

This is science-fiction, surely…

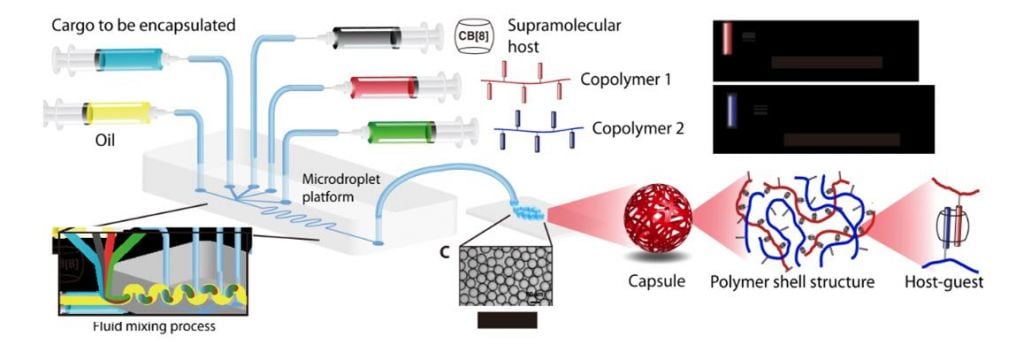

‘Self-healing’ polymers have been investigated for Biomimetic properties for a while (seeing as biomimicry is a major source of Biotech innovation!), using nano-tubes or encapsulated ‘healing agents’ to plug the gap and harden cracks.

Such non-biological materials include silicone polymers like polydimethylsiloxane (PDMS), which would be released on tension-related rupture of their capsules during cracking or damage to the concrete (or wall). You can read more on different chemical healing agents tried out in this review by PCI Mag here.

However, the Materials for Life (M4L) project now looks to integrate actual living organisms into the mix, which will work synergistically with the healing agents (so biomimetics and the real thing). The bacteria are also entombed in microcapsules, which are strategically embedded into the concrete matrix. Under stress from a fissure or sudden fracture, the bacteria-polymer cocktail is thus released, which then colonizes and forms a biofilm on the crack surface.

Overtime, these particular bacteria secrete Calcium carbonate (CaCO2 – much like reef forming corals) which hardens, supports and seals the fissure.

Investors into the project trial include the Engineering and Physical Sciences Research Council (EPSRC) as well as industrial support coming from the UK construction firm, Costain. The M4L are actually using one of Costain’s construction sites to test the prototypes, located off the A465 in the South Wales Valley area.

In total, 6 test concrete walls have been assembled with the embedded microcapsules, which will be put under various different tensile forces to induce fractures. The M4L team will then observe how the bacteria capsules work to repair these cracks, followed by comprehensive durability testing.

Despite this being the first ‘industrial’ trial of such a prototype, it is not the only example of research in the UK on how to use bacteria to reinforce concrete. The University of Nortumbria in Newcastle (NE England) has a team led by Alan Richardson, who have been investigating the use of the ground borne bacteria Bacillus megaterium in more of a preventative role against infrastructural damage.

However, in results the Northumbria team published in 2014, they found that whilst the bacterial concrete helped improve density and reduce permeability of the matrix, the nutrient ‘broth’ actually weakened the concrete when compared to the control.

Hopefully for the M4L team then the answer to self-healing concrete lies in post-damage cultures as opposed to the ‘concrete cancer’ solution (as cool as it sounds). This is a super interesting area of research which therefore marries two seemingly incompatible industries; Biotech and Civil Engineering.