High-value metals make the modern world go round, but the way we extract and dispose of them is far from sustainable. Biomining could be an elegant and lucrative alternative.

From the gold and silver in consumer electronics to the rare earth elements needed to power renewable energy technologies, metals underpin the transition to a high-tech, low-carbon economy.

It’s estimated that precious metals worth billions are lost every year from electronic waste alone, the vast majority of which goes unrecycled. There are growing concerns around the environmental and humanitarian effects of conventional mining practices. In addition, many countries seek to reduce their reliance on mineral imports to distance themselves from tensions between the West and China — a major supplier of precious metals and rare earth elements.

Fortunately, there is an emerging alternative. A wealth of microbial species, often from extreme environments, have evolved the ability to extract metals from their surroundings. Some produce acids and metal-scavenging proteins to dissolve metals from solid rocks, in a process called bioleaching. Others employ their own cell walls to extract and accumulate metal ions from liquids. By harnessing these miniature miners, the emerging field of biometallurgy could tackle many of the issues associated with conventional metal supply chains.

Trash to treasure

In Germany, a company called BRAIN (Biotechnology Research and Information Network) is leveraging a huge collection of more than 50,000 microbes to identify the most talented metal-extracting microbes and put them to work.

“BRAIN’s engagement in biometallurgy was, as is so often in science, a coincidence: in 2008, when we were working on surface-active biomolecules, we observed that a bacterial strain originating from our microorganism collection attached very selectively to hydrophobic gold surfaces. At this moment, the idea of a biological gold tweezer was born,” explained Esther Gabor, BRAIN’s Manager Technical Business Development.

The recovery of gold from electronic waste is a major target for BRAIN. The company also has its sights set on other waste streams that contain valuable metals which would otherwise be lost, or heavy metals that pose health and environmental risks. For example, ashes from incinerators, dust from steel production, and even sewage sludge contain recoverable amounts of precious and heavy metals.

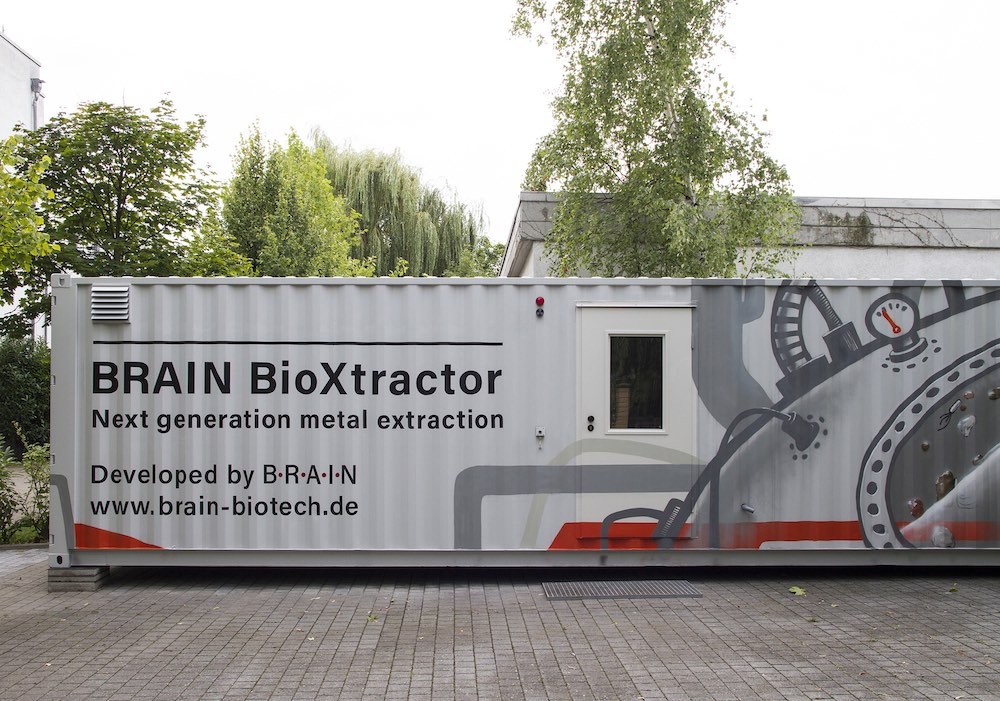

BRAIN’s most advanced biomining product takes the form of a modular, shipping container-sized unit called the BioXtractor. The unit contains all the necessary components for the bioleaching of precious metals, and is designed to be a flexible option for industrial companies looking to extract metals from various waste streams.

In a process that takes up to 48 hours, finely ground waste is incubated with the biomining microbes. Once they have leached out the metals, these are recovered from the mix using an adsorber resin.

“The major advantage is the sustainability of the processes,” said Gabor. “It replaces aggressive or toxic chemicals by microbial biomass and significantly reduces the energy demand and consequently the CO₂ footprint of metal recovery processes by a factor of three compared to the virgin mining and chemical recycling of gold. Compared to pyrometallurgical recycling (smelting), the CO₂ footprint is still reduced by a factor of two.”

So far, the company can make this process work in vats of 600 liters. The next step will be the construction of a pilot plant. BRAIN has built a collection of microorganisms that will let it create and customize new processes for different metals and rare earth elements. Currently, the company only uses naturally occurring microbes to avoid GMO regulations, which can be quite strict in Europe.

“We aim at reducing regulatory hurdles by using non-GMOs in biomining. However, there is a big promise of process improvement by using genetically enhanced microbes,” said Gabor. “I think that both politics and industry have the task of convincing society of the advantages that new technologies, such as gene editing, bring.”

Cities as urban mines

Another emerging player in biomining is New Zealand startup Mint Innovation, which aims to create ‘urban mines’ by having a precious metal biorefinery in every major city around the world.

Mint Innovation’s co-founder Will Barker used to work for LanzaTech, a company that uses microorganisms to capture industrial waste gases and transform them into fuel and chemicals. “Knowing that the process of biosorption would be best suited to small volumes of high-value waste, he looked to prove that gold could be recovered from printed circuit boards,” said Thomas Hansen, Mint Innovation’s Commercial Lead.

“Electronic waste is a very attractive feedstock as it has concentrations of gold hundreds of times higher than gold ores and there is not currently a localized solution for its recycling.”

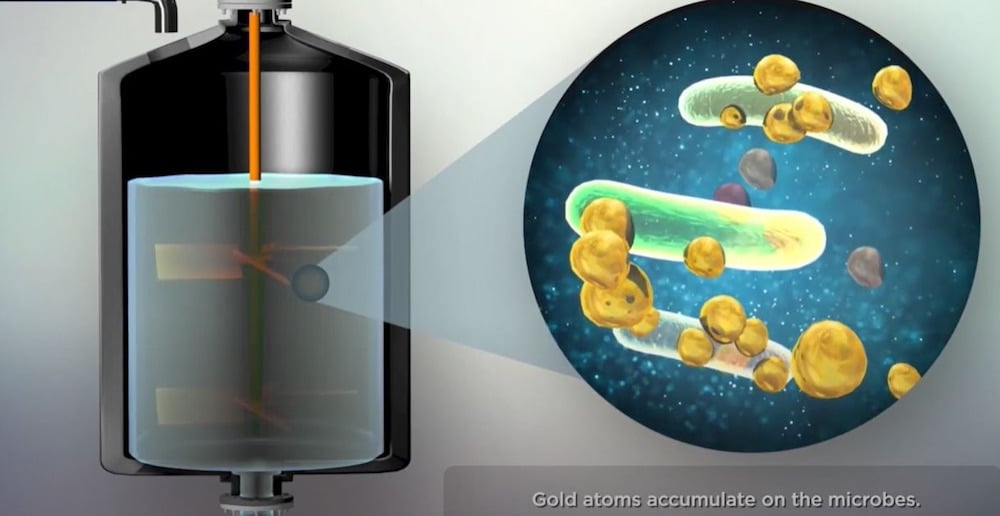

The company grounds e-waste into a powder, adding acids and oxidants to dissolve the metals into a liquid solution, where the microbes are able to find gold and accumulate it on their surface. The gold-coated microbes can then be filtered out and refined to liberate the precious metal.

“We don’t have any emissions or toxic waste so we like to compare ourselves to a microbrewery in scale and impact on the local area — although we don’t have a tap room,” Hansen explained.

Hansen hopes that the low-impact, low-waste, low-carbon nature of this technology will make it an attractive solution for cities around the world looking to develop their own precious metal circular economies as opposed to shipping their e-waste abroad, as is often the case currently.

“People are often skeptical of novel technologies, especially when intangible processes like ‘biosorption’ are involved. Our discussions have mainly been focused on educating recyclers of electronic waste about our process and its benefits to them. They are definitely excited to have a better alternative to the status quo and will be the bulk of our early customers. The smelters don’t really effectively return value to recyclers for the waste they send for recovery and many think the current market is broken,” said Hansen.

Space biomining: the final frontier

“As humanity’s presence in space plans to expand, we need to understand how to generate local resources and become independent from a constant resupply from Earth. The farther from Earth we plan to travel, the more important this becomes. From this point of view, the extraction of useful materials in space represents a promising solution. Besides, some asteroids are rich in precious and rare metals,” said Rosa Santomartino, Postdoctoral Research Associate in Space Microbiology at the UK Centre for Astrobiology.

Santomartino is part of a scientific team that conducted a three-week biomining experiment conducted aboard the International Space Station in late 2020. The results revealed that one species of bacteria could enhance the removal of rare earth elements from basalt rock on the Moon and Mars by up to over 400%.

“We are just beginning to understand how to exploit the process in space… for instance with probes that will capture asteroids and inject the biomining solution. Biomining in space will still require robotic missions, but the advantage [of microbes] resides in lighter hardware, avoidance or reduction of drilling the rock surface, and the automatization of the process,” said Santomartino.

“Understanding how microbes interact with terrestrial and extraterrestrial rocks in space will also provide insight on space applications other than biomining,” she added. For example, microbes could be used to transform rocks into fertile soil, produce biofuel, or recycle multiple materials. These are just a few of many applications of biotechnology in space, which could perhaps even lead us to a fully-fledged space bioeconomy in the decades to come.