Stay informed about the latest clinical trial news, including the latest developments and outcomes of ongoing clinical trials, new innovative trial methodologies, clinical trial challenges, clinical trial destinations, and the evolving regulatory landscape.

In Depth 24 Apr 2024

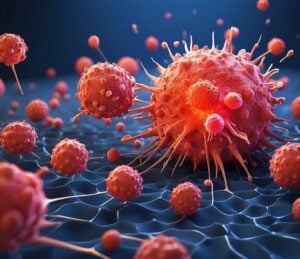

Overcoming toxicities: are IL-2 smart cytokines the next big thing?

A more advanced form of IL-2 cytokine therapy called IL-2 smart cytokines could overcome side effects, and shake up cancer care as we know it.