Although most gene therapy still relies on non-infectious viral vectors for delivery, a recent venture financing round for the Swiss company Anjarium Biosciences has shone the spotlight on alternative vectors, including lipid nanoparticles and electric pulses.

Last month, Anjarium Biosciences raised €51M (CHF55.5M) in a Series A financing round to advance its gene delivery system based on DNA vectors and other proprietary nanoparticle technology. The round was led by veteran investors Abingworth and Gimv, and also included Pfizer Ventures, Omega Funds, and Surveyor Capital.

Gene therapy has taken off in recent years, with treatments such as Spark Therapeutics’ Luxturna for the treatment of inherited blindness and Novartis’ spinal muscular atrophy therapy Zolgensma blazing a trail and exciting investor interest. The vast majority of marketed gene therapies deliver their therapeutic genes using viral vectors such as adeno-associated virus.

However, important safety, efficacy, and manufacturing hurdles remain for the gene therapy field. For example, getting fragile genetic material to cells without causing significant side effects or having the immune system attack the therapy midway is proving even harder than scientists had thought.

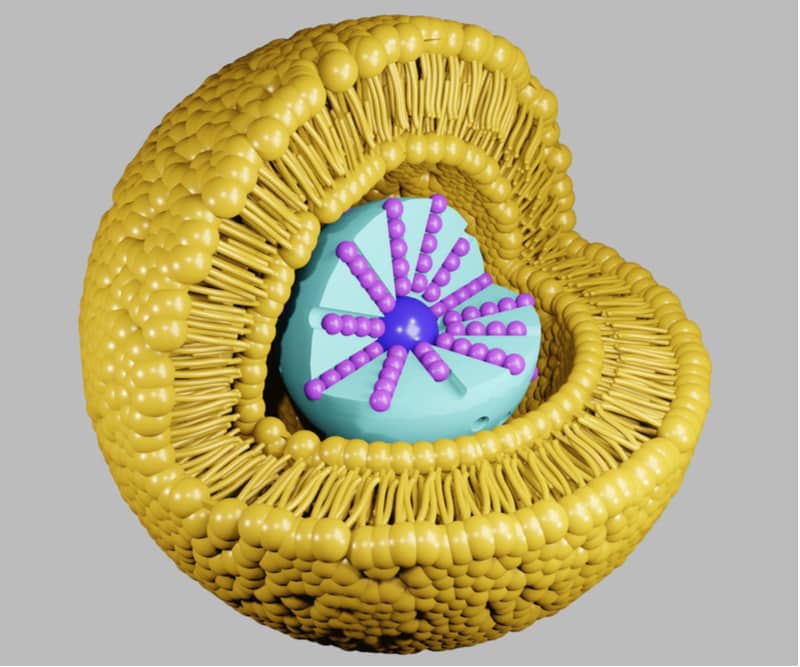

“Gene therapy delivery in general is a rather complex challenge,” said Joël de Beer, Anjarium’s CEO. “Looking at all natural efficient delivery systems, there are two important parts – one is protection of the delicate cargo within a shell, and the second is having surface ligands on it to interact with specific cells.”

Anjarium’s basic philosophy is to mimic the gene transfer mechanisms developed by viruses and the body’s own cells. Rather than using viral vectors, it packages gene therapies into carriers that are a fusion between synthetic carrier molecules such as lipid-based nanoparticles and natural ones such as exosomes.

“A great example would be [the virus responsible for Covid-19] – if you look at graphics on the Evening News you see a shell that has a corona or ‘crown’ of spikes on its outside, which is actually a receptor that leads to cell-specific delivery of its delicate cargo,” explained de Beer.

“Inspired by such specific delivery systems, including extracellular vesicles, it’s this stable cargo protection and cell specificity that we want to biomimic.”

Anjarium’s hybrid capsules blend the low toxicity and immune tolerance of natural carriers with the tunability and durability of synthetic carriers, and could be more specific and longer-lasting than current delivery vehicles. Additionally, the company can carefully tailor the size and characteristics of the hybrid carrier to suit the gene therapy’s target, for example, solid tumors.

The Covid-19 pandemic has had a rollercoaster effect on gene and cell therapy companies. Initially hit by a slurry of trial delays caused by the lockdowns, some of them shifted gears and helped in the manufacture of components for Covid-19 vaccines. Since the start of the pandemic, funding for companies developing cell and gene therapies has hit record levels.

The rise of Covid-19 vaccines based on messenger RNA (mRNA), such as those from BioNTech/Pfizer and Moderna, has already showcased the potential of delivering genetic material to the body via lipid nanoparticles instead of viral vectors. Other alternatives to viral vectors in development include delivering DNA to tissues via electric currents, as developed by the Parisian firm Eyevensys, and transfection, a technology that relies on small DNA molecules called plasmids to carry genes to cells.

“Viral vectors have enabled the first generation of commercialized cell therapy products; however, next-generation therapies will require more complex engineering including multiple gene edits that will require a non-viral solution,” said Michael Maguire, the CEO of the Irish biotech Avectas. Avectas is developing ways to genetically engineer cell therapies in the lab without using viral vectors.

“The biggest limitation is space in the viral capsid, followed by cost and inflexibility in manufacture,” Maguire added. “Non-viral delivery platforms are advancing rapidly towards the clinic with electroporation, lipid nanoparticles, and physical or chemical transfection systems competing.”

Gene therapies using viral vectors have often faced safety scares. Last month, for example, a clinical trial for Biomarin’s gene therapy for the rare disease phenylketonuria was put on hold after mice given the treatment developed tumors in a preclinical study. Shortly after, a clinical trial of a rare disease gene therapy from the firm Astellas was also paused after the death of a patient.

Additionally, the immune system can build antibodies against viral vectors, preventing more than one use for each vector for each patient. And to mass-produce viral vectors, one typically needs to grow them in cell cultures, a process that can be messy and lead to impurities.

While non-viral vectors could avoid many of these issues, stability of both the carrier and the genetic material can be a major problem. Nanoparticles can also have their own toxicity inside the body, while the safety profile of other synthetic carrier technologies may be less established than that of more traditional vectors.

UK-based biotech SiSaf claims major stability, safety profile, manufacturing costs, and targeting improvements of its own delivery platform, made of biodegradable silicon and other components that break down into micronutrients. Still, challenges remain.

“In general, non-viral vectors are simple in theory but complex in practice,” said SiSaf’s CEO, Suzanne Saffie-Siebert. “Apart from intracellular and extracellular barriers, non-viral systems need to overcome other challenges in order to increase the effectiveness of non-viral gene transfer. Issues of production, storage stability, and formulation suitable for multiple applications [are] still unresolved.”

“This is why in spite of various developments in liposome, polymer formulation, and optimization, new compounds are constantly being proposed and investigated.”

5 October 2021: A correction was made to a description of SiSaf’s platform to say it’s made of biodegradable silicon. Cover image via Elena Resko.