Researchers from the Manchester Institute of Biotechnology are working in engineering a microbe capable of producing propane – an increasingly important fuel.

Propane is an emerging fuel, used from heating to transport fuel. Therefore, producing it via synthetic biology has been a major target in the biofuel field to be Greener.

Propane is an emerging fuel, used from heating to transport fuel. Therefore, producing it via synthetic biology has been a major target in the biofuel field to be Greener.

This is especially because biobased propane it’s a very good drop-in replacement of fossil fuels. So, it could use exactly the same infrastructures that exist now for propane sourced from petroleum.

However, there is a significant challenge – there are no natural metabolic pathways that produce propane. A team (from Imperial College London and the University of Turku) already had success in engineering a new propane-producing pathway.

Now in collaboration with the Manchester Institute of Biotechnology, this work was built on to create an alternative pathway – that tackled previous limitations in the amount of propane bacteria could produce.

This alternative pathway required researchers to find an enzyme that could make propane, and then engineer bacteria to use this enzyme.

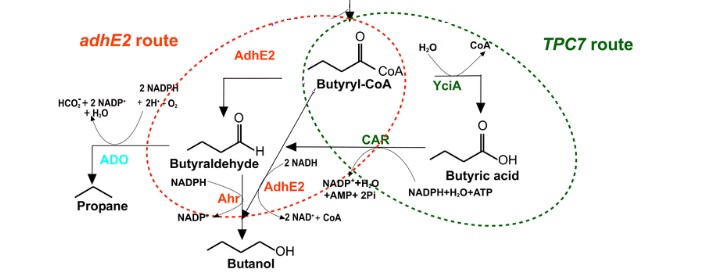

The chosen enzyme was ADO, found in algal cyanobacteria. This enzyme had already been used to make butanol, and the research team modified its amino acid sequence and structure so it could make propane too.

Once this useful enzyme variant was ready, the next step was to ‘persuade’ a suitable microbe (the ever so versatile E. coli) to use it – which is where metabolic engineering comes in.

Because the metabolic network of a microbe works a bit like a transport system, the researchers had to make sure the microbe could supply the molecules (butyraldehyde) the ADO enzyme uses as a substrate. It also blocked non-essential pathways that did not lead to propane production.

After all this work (published in Biotechnology for Biofuels), the research team is confident that this microbial platform has real promise, and it can already produce a substantial amount of propane.

The next step is looking into optimising the process to be efficient enough for commercial exploitation.

Another challenge is to make this engineered microbe compatible with different feedstocks – ideally cheap waste streams like molasses or bagasses.

This is important progress in the GreenTech field, which had many exciting developments during 2015.