Newsletter Signup - Under Article / In Page

"*" indicates required fields

Paris-based PILI has raised €3.6M that will take its technology to produce dyes through microbial fermentation to an industrial scale.

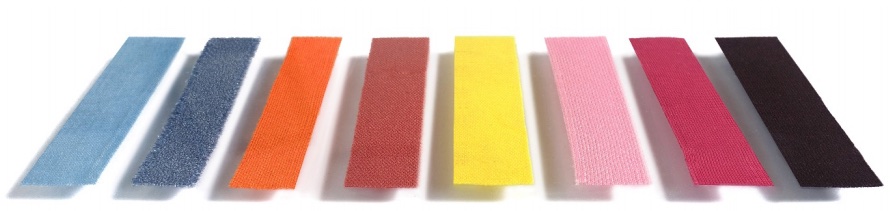

Founded in 2015, PILI seeks to disrupt the unsustainable production of dyes. Just in the textile industry, dyes are a €8B market. However, the production of these chemicals relies on petrochemical processes that require toxic solvents and vast amounts of water and energy.

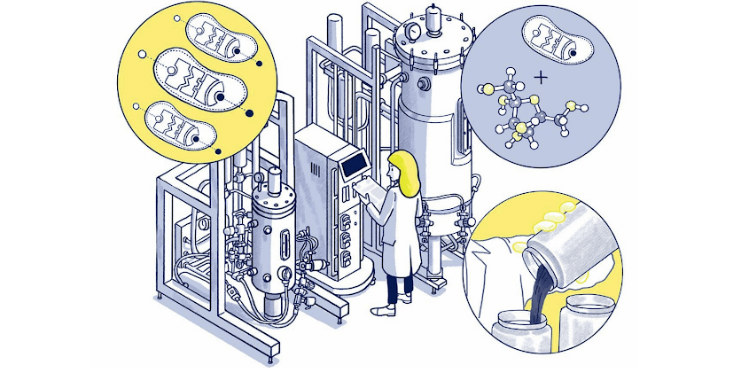

PILI aims to change this by replacing chemical processes with microbial fermentation. The company engineers the microbes to produce high-performance dyes that are resistant to fading. While the end product is the same, changing how they’re made can make a big difference.

“We can divide the amount of water needed by 5 and cut CO2 emissions 10-fold during the production of dyestuff,” Guillaume Boissonnat, Chief Science Officer of PILI, told me. “We also avoid the use of 100 tons of petroleum and 10 tons of toxic chemicals per ton of product.”

With the new funding, the company plans to take its technology to pilot scale and to validate the performance of its dyes with its industry partners. Adenis estimates the production will reach the kilogram scale in 2020 and the first products will be sold one or two years later, when the production is expected to reach industrial scale.

Among the investors are the deep tech VCs Elaia and SOSV. The latter had previously invested in PILI when the company took part in its renowned accelerator program RebelBio. Other investors include business angels and the French government.

The fashion industry is well known for its huge environmental impact. In recent years, this has driven multiple companies to seek more sustainable alternatives to the toxic petrochemical processes used to make and dye clothes. Another player in the field is Algalife, in Germany, using algae to produce both fabric and dyes.

Images via PILI

Partnering 2030: FME Industries Report