The Swiss biotech Sun Bioscience has launched a robotic platform designed to standardize the production of 3D cell models of organs called organoids, making it easier to personalize treatments to a patient.

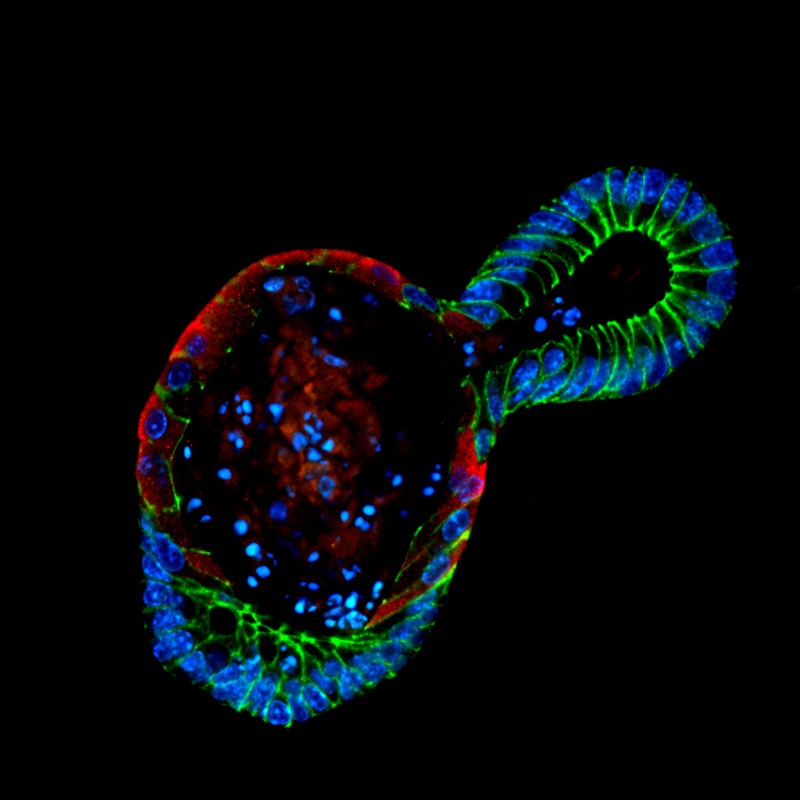

Organoids are clusters of cells grown in the lab, and developed into miniature organs, such as the brain or intestine. Often no bigger than a grain of rice, they can be used to model a patient’s body tissue to perform drug screening tests, helping to personalize treatments to that patient.

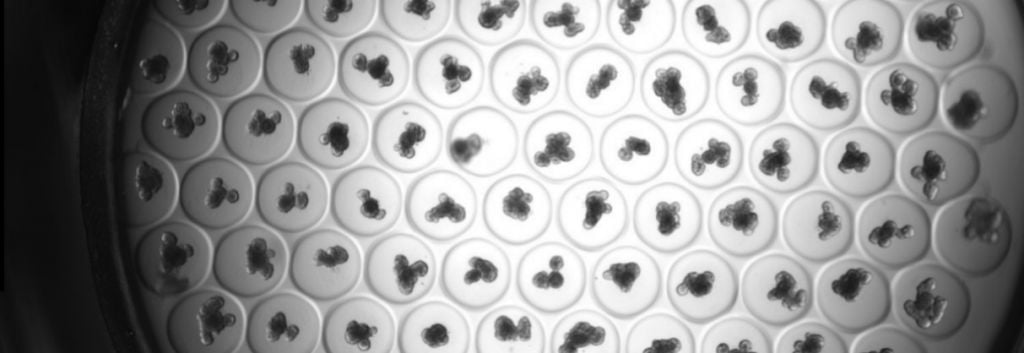

For many organoid growth platforms, organoids are grown in microwells. This process is hard to standardize and it is difficult to produce them in large quantities. Furthermore, automated imaging of these organoids can be tricky due to light diffraction around the plates, making more work for researchers.

Sun Bioscience’s robotic platform is designed to solve these issues. “The main advantage of our platform is the structured hydrogels with crystal clear imaging capacity, allowing automated image-based screenings,” a spokesperson from the company told me.

In addition, the company’s platform grows each organoid in a U-shaped microwell that is thinner than the shallow microwells normally used. The company’s spokesperson told me that this lets you grow more organoids at a time, and also helps to standardize the number of stem cells each organoid is made up of.

The system has been used to grow different types of organoids, including those made up of retinal and intestinal tissue.

Sun Bioscience’s technology is being used in a clinical pilot study hosted by the École Polytechnique Fédérale de Lausanne. The trial compares intestinal organoids grown from the cells of cystic fibrosis patients with organoids from healthy volunteers. “The goal of the study is to validate that these new readouts are accurate and sensitive enough to diagnose cystic fibrosis and to understand treatment efficacies for the patients,” the spokesperson explained.

If the clinical pilot goes well, the organoid platform might even be able to detect the different mutations in cystic fibrosis patients and inform the best treatments for these patients.

The launch of the organoid platform follows a €50,000 EU grant awarded this year, as well as a €88,000 (100,000 swiss francs) prize from the Swiss startup sponsor W.A. de Vigier Foundation.

As part of the EU project, Sun Bioscience expects to produce and sell 1,000 units of the organoid platform. It hopes to generate revenues of more than €2M within three years.

Organoids make a busy branch of biotech. This year, the first 3D organoids of placental tissue were developed in two parallel studies. Other companies, such as the UK company Cellesce and Dutch biotech Ocello, offer organoid growth services for drug discovery screens. However, Sun Bioscience appears confident that its own platform can compete in this specialized field.

Images from Sun Bioscience