Newsletter Signup - Under Article / In Page

"*" indicates required fields

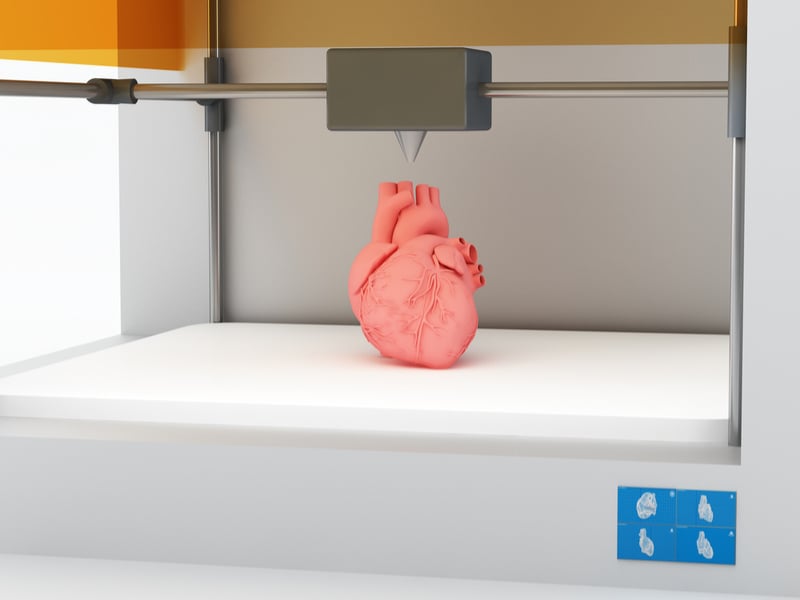

The Oxford spin-out OxSyBio has secured £10M (€11,26M) to develop a 3D tissue printer that uses liquid droplets to design and regenerate tissues.

Founded in 2014, OxSyBio is developing a technology to 3D print living tissues in order to replace body parts that are damaged by disease or injury. The substantial Series A funding was provided by Woodford Investment Management, one of the largest investors for early stage biotech companies.

Printing living tissues in high resolution is difficult to do because cells move around on the printed structures and can collapse on themselves. Furthermore, current printing methods use UV light or heat to mold the structure of the tissue, which can damage the living cells.

To overcome these challenges, OxSyBio uses 3D networks of lipid-coated aqueous droplets to support the structure of the printed tissue and assemble it into living structures. Importantly, the liquid droplets are about the same size as the body’s cells and can be positioned with sub-micron precision. Thus, new cells can be placed in the droplets with a high degree of accuracy.

OxSyBio faces competition from the Dutch biotech Iamfluidics, which is working on a tissue printing method that uses in-air microfluidics. Spun out of the University of Twente, the company is exploring the use of jets to speed up the tissue printing process.

Another competitor, US software firm Advanced Solutions, has developed a 3D human tissue printer operating on a six axis robot. The printer can be combined with vascularization technology to mimic a functioning human liver.

While many attempts at 3D organ printing are being made, successfully supplying the regenerated tissue with nutrients has been a major hurdle for biotechs. Even though OxSyBio will face the same challenges as other biotechs, the company may set itself apart from its competitors through the increased precision its technology enables in designing regenerated tissue.

Images by Andrei Nekrassov, belekekin/Shutterstock