Is the Future of Biotech…Green? The Algae Industry ranges from Biofuels to Nutrition to Fashion and Microalgae hold lots of potential for the industry to expand. But why? And do Venture Capitalists agree?

Microalgae have already been established as incredibly valuable to the biotech industry, in part due to their ancient genetic diversity and resilience, providing a bio-platform for production of food supplements, biofuels and even aesthetic effect (see Algaemy from Berlin).

So what kind of Industries are looking to Exploit Microalgae?

Who is working in the Algae-based Biofuel business? Well, a vast number of biotechs – and start-ups (such as Solaga in Germany) look to make certain processes (such as waste remediation) economically sustainable by producing biogas on the side. Here we’ll just mention a few in Europe…

UniVerve (Israel) has begun to scale-up its process for algae cultivation. The extracted oil, using wet extraction tech, can be used as feedstock for all biofuels, and produced relatively cheaply.

AlgaEnergy (Spain) also demonstrates that pursuing algae for biofuels is very desirable since yield is very high, it uses either wastewater, brackish or seawater, and does not require the use of agricultural land (a major plus).

But the scaling up of cultivation of any such microbial process (similarly for algae) can be challenging for a range of reasons. This has led to the development of Algae raceways, which are like shallow ‘running tracks’ for the culture, giving maximal exposure to sunlight to promote aerobic respiration.

AlgaEnergy’s industrial Plant “Arcos de la Frontera” near Madrid, has the goal of fixing the CO2 emissions from industrially originated real flue gas by using microalgae cultures, transforming this noxious gas into biofuel products.

Algenol (Germany) employs enhanced blue-green algae (or cyanobacteria) photosynthesis to convert CO2 and seawater into “sugar” (pyruvate) and then into ethanol and biomass. Evodos (Netherlands) on the other hand is a developer and manufacturer of “Dynamic Settlers” (Spiral Plate Technology) to separate out algae from other materials in the process.

The Technology University of Munich (TU München) has built a unique €10M global-climate simulating Algal plant on the Ludwig Bölkow Campus in Ottobrunn (Bavaria).

Able to cultivate algal strains from all over the world, the research team hopes this will allow them to study and discover new types to be exploited by Biotechs for biofuel production, which is of high interest to Aviation companies such as Airbus, alongside other renewable energy-focused industries in Germany.

The Algae Tech Facility is also part of the “AlgenFlugKraft” (Algae Aircraft Fuel) project, backed by the Bavarian State Ministry of Economic Affairs.

AlgoSource Technologies(France) worked alongside the CNRS, Université de Nantes and Ecole des Mines de Nantes to develop a bio-bitumen, very similar to the “real” bitumen used for making roads. It produced bio-bitumen using microalgae residues to form soluble proteins from the cosmetics industry.

They used a method of hydrothermal liquefaction, where the microalgae waste is transformed into a hydrophobic black viscous phase (organic-bitumen) with a similar appearance to the oil.

Then there is the development of potential Algae plastics. The Institute for Plastic Technology in Valencia (Spain) profiled its an EU program looking into creating adhesives, paints, and dyes using an algae-based technology developed by Biofuel Systems in Alicante. The 42-month research program includes 13 different companies and the first stage of the project will be to identify fast-growing algae strains.

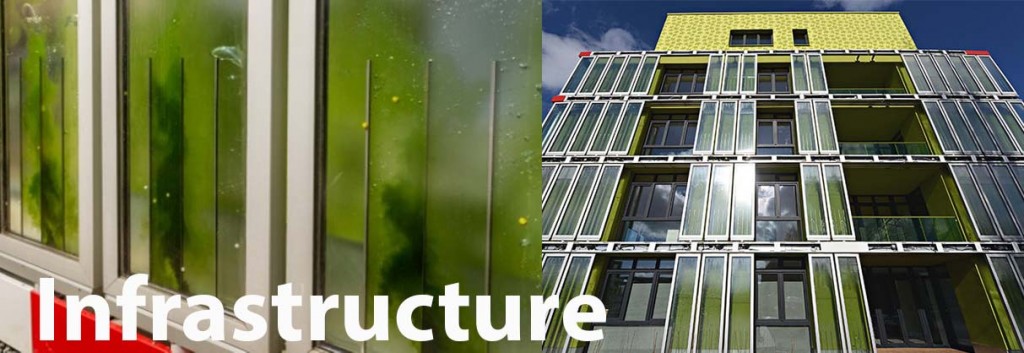

And then there is one of Arup‘s innovative-design buildings in Hamburg (Germany) which is entirely sustained by an Algae bioreactor system (developed by Colt International). This algae panel system encasing the building produces biomass whilst insulating the rooms from noise, cold and generates a natural source of heating.

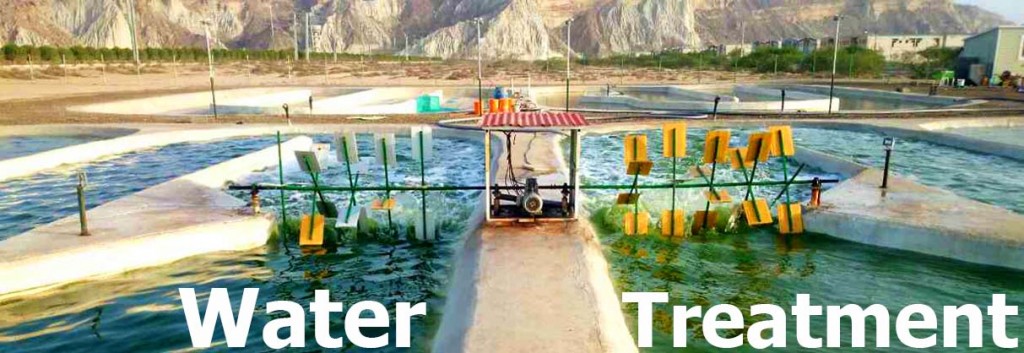

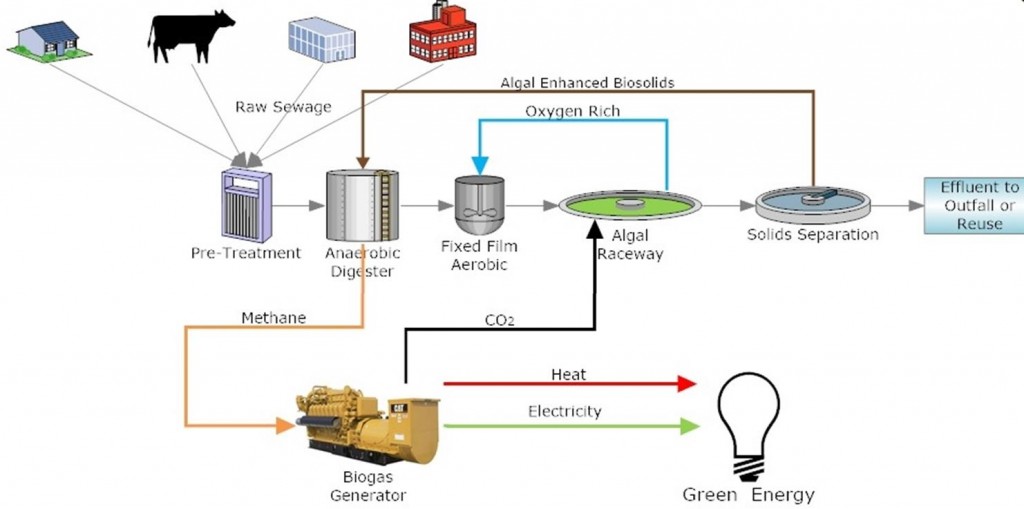

Waste-water treatment using algae is another source of Green-tech-novation for Algae (known as ‘scrubbing’), particularly when combined with other microbes in a cycle. The World’s First ‘Phycoremediation plant’ to treat industrial effluent was commissioned in SNAP Natural and Alginate in Ranipet (India).

First, the water is run through an anaerobic bacterial bioreactor which produces oxygen and biogas, which is then used in the second aerobic algae reactor (followed by cycling on the Algae Raceway). In a kind of biotech symbiosis, the algae cultures produce CO2 for the bacterial reactor, and the bacteria generate O2 for the algae.

Aquanos (Israel) is an example of such a system which addresses the problem of efficiency in this process, well ahead of Cambridge researchers looking to do the same. Their two-step bioreactor system (dubbed ‘The Gemini’) dramatically cleans out organic waste from industry effluence by 70-80% with one run, and up to 95% on the second run – amazing!

So we’ve discussed using algae to generate biomass in Biofuels production, but it is well known that algae and its many forms (including seaweed) have been a staple food source for many cultures for thousands of years.

However, did you know many in the industry are now working on algae as alternative sources for many popular soft drinks and dietary supplements too? Even the European Space Agency is looking to algae as a long-term food source for Astronauts.

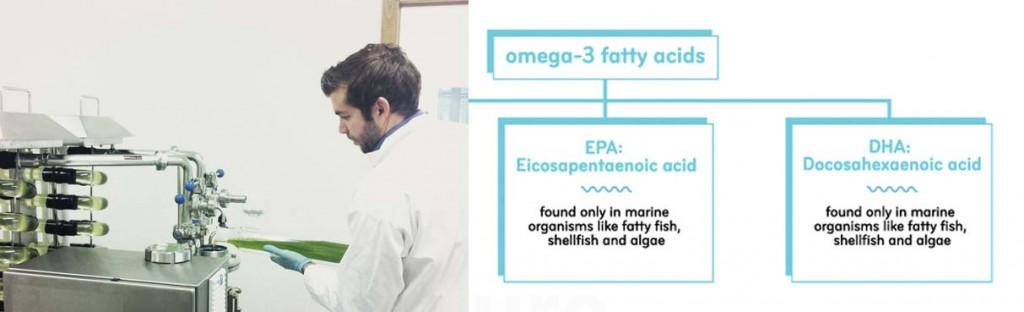

For example, could Algae reduce Fishing Demand for Omega-3 Oil? The Neofood project from the Basque Country (Spain) is searching for novel Oceanic strains of algae in salt-marshes around the coast, specifically those that produce docosahexaenoic acid (DHA) as a dietary supplement. Since DHA is the main type of Omega-3 acid derived from fish oil, an algal alternative to such a non-sustainable source is very desirable in the Biotech industry.

Others looking for same include Fermentalg (France), a 7-year old industrial biotech which last year received the European Novel Food authorization for its first DHA product for the vast human nutrition market. Then you have Qualitas Health (Israel) and Simris Alg (Sweden) with marketed ‘vegan and GMO-free’ Omega-3 fatty acid algae platforms.

Simris’ Hammenhög microalgae farm is also partnered with the AlgaePARC in Wageningen (Netherlands), one of the largest research projects on the industrial macro-scale cultivation of microalgae in Europe.

Algama (France) is also a start-up, instead looking to make Spirulina algae tasty in a drinks based product, although they have to compete with B-Blue (Belgium) and Spiralps (Switzerland).

Then AlgaTechnologies (Israel) have an extensive food and beverage range of microalgae-based formulations (from Astanaxin) known as AstaPure. And TomAlgae (Belgium) is developing freeze-dried microalgae for feed in shrimp hatcheries with its own microalgal “cultivar” (a freeze-dried product).

Astaxanthin, can cost up to €20k per kilo, although it is a naturally occurring carotenoid in red algae, and it is now being investigated pre-clinically as a dietary supplement with powerful antioxidant effects.

GlycoMar (Scotland) is an Algae specialist in the Biotech industry which has now funded a joint venture, Prasinotech, with MicroA (Norway). Prasinotech will be the first in the world to refine the production of such polysaccharides and from microalgae.

Another such project involving astaxanthin (i.e. the pink protein which makes flamingoes pink) is at the Symbiosis Center Denmark, where Ph.D. students from the Technical University of Denmark (DTU) are researching how to use the MicroAlgae ‘Cathedral‘ there to grow it.

Diatoms (microalgae with silica-based ‘shells’) are also now being investigated to kill cancer. A University of South Australia research group worked out how to create an algae-encapsulated chemotherapy using nanoparticles.

The international team published a paper in Nature Communications which included collaborators from the Dresden University of Technology (TUD) in Germany, and their Kröger Group at the B CUBE Centre for Molecular Bioengineering for their expertise on biomimetic materials.

Genetically engineered diatom biosilica releases drug molecules in the immediate vicinity of the target cells. (Source: Delalat et. al 2015, Nature Communications, 6, 8791, doi: 10.1038/ncomms9791)

Also at the TUD, research on microalgae has even extended to the use of algae as Biosensors with 3D-Printing (a revolutionary tool in medtech discovery and biohacking). But this is just scraping the surface of Microalgae’s potential in Medicine.

So why isn’t everyone investing in microalgae?

Well, the problem at the moment is that many of these processes are still working to reduce the cost of using microalgae (compared to oil prices – which are quite low at the moment). And whilst there is a lot of research into how such start-ups can simply make more algae, faster…and more sustainably, this is perhaps not necessarily enough to convince big Venture capitalists to share the same green vision in Europe (it is admittedly a different story in the US with giants like Solazyme etc.).

I was speaking to someone in the EU start-up industry recently, and he told me there is also a sense that the European Algae community is on a bit of a precipice with Investors at the moment – should such US leaders fail to demonstrate scalability (and proof-of-profit), it could permanently damage the faith these VCs have in the industry as a whole…

So we look on to see which will be the Biotech to really kick-off the financial Algae Craze (if at all) and whether the industry can sway the public of the true value Microalgae holds for the Future.