Newsletter Signup - Under Article / In Page

"*" indicates required fields

The well-known but stubborn FAS enzyme has been successfully modified to make petrol and jet fuel. This research opens up possibilities to produce biofuels with engineered microorganisms, or “cell factories”.

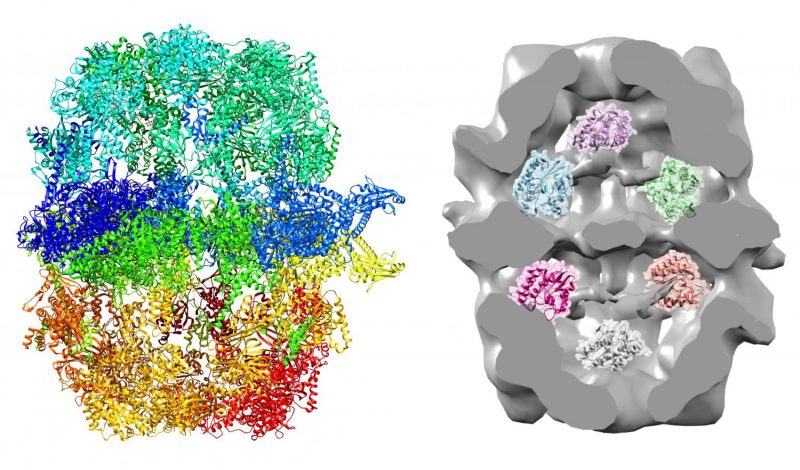

Researchers from Chalmers University of Technology in Sweden have developed a method to modify the enzyme fatty acid synthase (FAS). This complex enzyme has long been a target of research, due to its role in producing hydrocarbons that could be of interest for biofuels. Until now the enzyme had proven hard to engineer. Now published in Nature Chemical Biology, the research work achieved an unexpected success in getting a FAS with novel capacities.

The strategy consisted of replacing domains of a fungal FAS enzyme with those from foreign enzymes. Counter to the researchers’ expectations, this tinkering worked. The modified FAS enzyme could now synthesize medium chain fatty acids and methyl ketones, instead of its usual long chain fatty acids. The new molecules are components currently used in transportation fuels, and the enzyme could yield biobased alternatives for petrol and jet fuel, for example.

Although enzymatic engineering is an old tool for industrial biotech, there has been a certain resurgence in interest for novel enzymes, which remains one of the biggest challenges in SynBio. For example, it’s the focus of the new SynBio program in Munich and other approaches with artificial enzymes.

For this particular enzyme, the next step towards its ‘sustainability mission’ is to be integrated with the yeast cell factories being developed at Chalmers. Once the enzyme is part of a cell’s metabolism, the cell factory could produce common fuels from glucose, derived from biomass.

The first steps towards a commercial reality have already been taken. There’s an application for a patent and a collaboration with Biopetrolia, a spin-off from Chalmers University and one of the companies founded by Jens Nielsen, one of most active scientists in technology transfer in European Biotech.

Images from tofumax/Shutterstock and Chalmers University of Technology

Partnering 2030: FME Industries Report