Newsletter Signup - Under Article / In Page

"*" indicates required fields

Carbios, a French biotech, has developed an environmentally-friendly method to break down the PET plastic fibers in textile waste using enzymes.

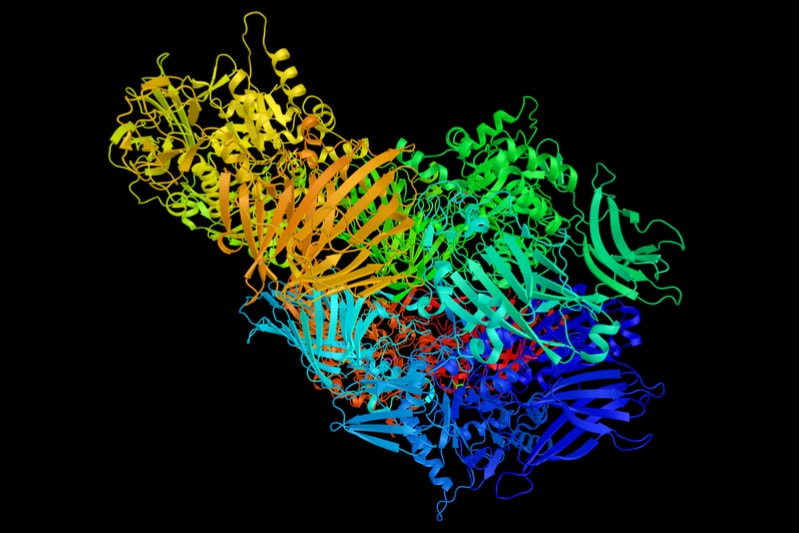

Carbios has developed a technology which can depolymerize textile waste fibers made of PET plastics into their original monomers. The technology uses enzymes to create biodegradable plastics and recycle existing plastics into their original compounds for reuse. According to Carbios, Plastic textile waste accounts for more of the waste from PET than plastic bottles. Carbios’ technology uses enzymes to break PET down into its main consituents, PTA (terephthalic acid) and MEG (monoethylene glycol). This is what makes the plastic recyclable.

In addition to textiles, Carbios is targeting plastic bottles, packaging and film and seeking out partnerships to achieve these goals. Last year, Carbios teamed up with TechnipFMC to bring their enzyme technology to an industrial scale. Furthermore, their technology has drawn the interest of L’OREAL, who signed an agreement with the French biotech to found a consortium for industrial-scale recycling of bio-plastics.

“In the future, we expect to have enzymes for each type of polymer. So we could have an iterative process to recycle any type of plastic, without the need for sorting, and we can recover the monomers that interest us,” Emmanuel Maille, director of Strategy and Development at Carbios, previously told us. The current news brings the company one step closer to achieving this goal.

While numerous approaches are in development by European biotechs to create sustainable forms of PET. For example, BASF is developing biodegradable polymers, such as Ecoflex. A noteworthy competitor to Carbios is Dutch biotech Ioniqa, which is developing a technology that uses nano-particles to depolymerize PET. Another Dutch company, Avantium is developing a technology to convert plant waste into plastic.

PET is the most commonly recognized plastic in the world and has a variety of uses from plastic bottles and packaging to textile fibers, or polyester. Each year, 43 million tons of PET are produced for the textile market, compared to 15 million tons for the production of plastic bottles. Most textile waste is currently sent to landfills or incinerated, highlighting the need for effective textile recycling technologies.

However, Carbios appears to be unique in their use of embedded enzymes in plastics and recycling to biodegrade PET textile waste. Their parallel development of enzymes in recycling and embedded plastics could give them an advantage over competitors by combating current PET waste as well as generating a new form of environmentally friendly plastics.

Images by Africa Studio, ibreakstock/Shutterstock

Partnering 2030: FME Industries Report